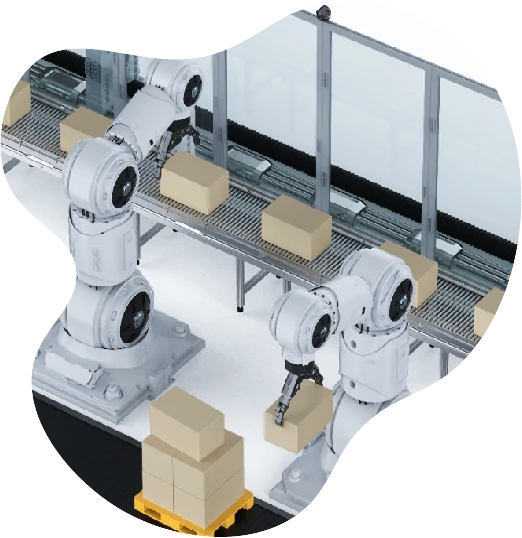

At DynoConv Engineering, we specialize in delivering innovative and efficient plant engineering solutions that empower organizations to achieve their strategic goals. Our comprehensive approach integrates the latest technologies and methodologies to design, develop, and deploy systems that are both robust and adaptable. With a strong commitment to quality and customer satisfaction, we aim to be your trusted partner in navigating the complexities of modern engineering challenges.

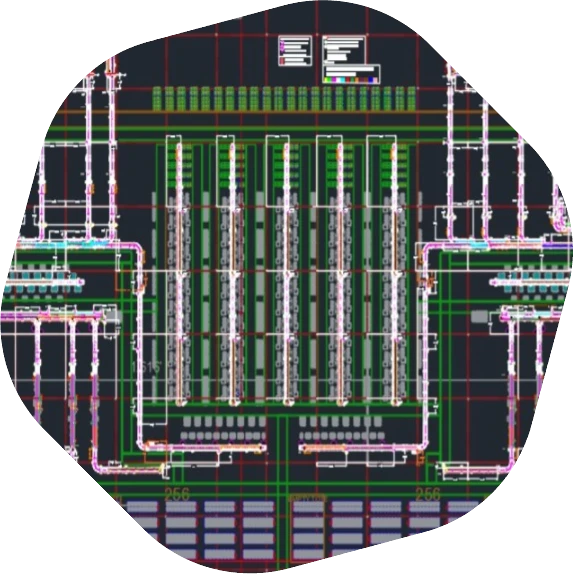

We utilize advanced software tools such as AutoCAD for detailed design and drafting, Emulate 3D by Rockwell Automation for virtual simulation and system validation, and Autodesk Inventor for 3D modeling and mechanical design to ensure precision and efficiency in all stages of system development.

We create a detailed layout that prioritizes product flow control, minimizing bottlenecks and enhancing operational efficiency throughout the facility.

Our design includes specific electrical call outs for essential components, such as power drops, control panels, and safety panels.

We identify and indicate locations for power drops to provide accessible electrical supply points that support equipment needs without overloading circuits.

We incorporate control panels in the layout to centralize operational controls, facilitating easy access for monitoring and adjustments while ensuring compliance with safety.

Our layout features safety panels for quick access to emergency shut-off systems, enhancing the safety and responsiveness of the operational environment.

We strategically position E-stop/start/stop stations throughout the facility to ensure immediate access for operators, promoting safety during critical situations.

We design line of sight zones to ensure clear visibility for operators, enabling effective monitoring of processes and quick decision-making to enhance overall safety and efficiency.

We create detailed drawings that facilitate the erection and assembly of product layouts, ensuring clarity and precision in the construction process.

Our expertise includes developing complete layouts that incorporate architectural elements, providing a cohesive design that meets all project requirements.

We design E-stop layout arrangements, ensuring that all safety measures are clearly integrated with complete control equipment for optimal functionality.

Our team meticulously identifies panel and power locations, providing dimensions to ensure accurate installation and accessibility.

We provide detailed elevation and sectional views with complete dimensions, aiding in the accurate erection of structures and components.

We develop effective power distribution layouts that clearly outline start/stop stations, ensuring efficient operation and safety throughout the system.

Our focus on complete dimensions throughout the drawings helps ensure that all installations are executed precisely, minimizing errors during the assembly process..